Crafting our micro-office Mission Control has been a great opportunity for us to experiment with many of the technologies we implement in our larger projects, such as natural materials, prefabrication, breathing construction and self-build techniques.

Let's look back at how Mission Control was actually made.

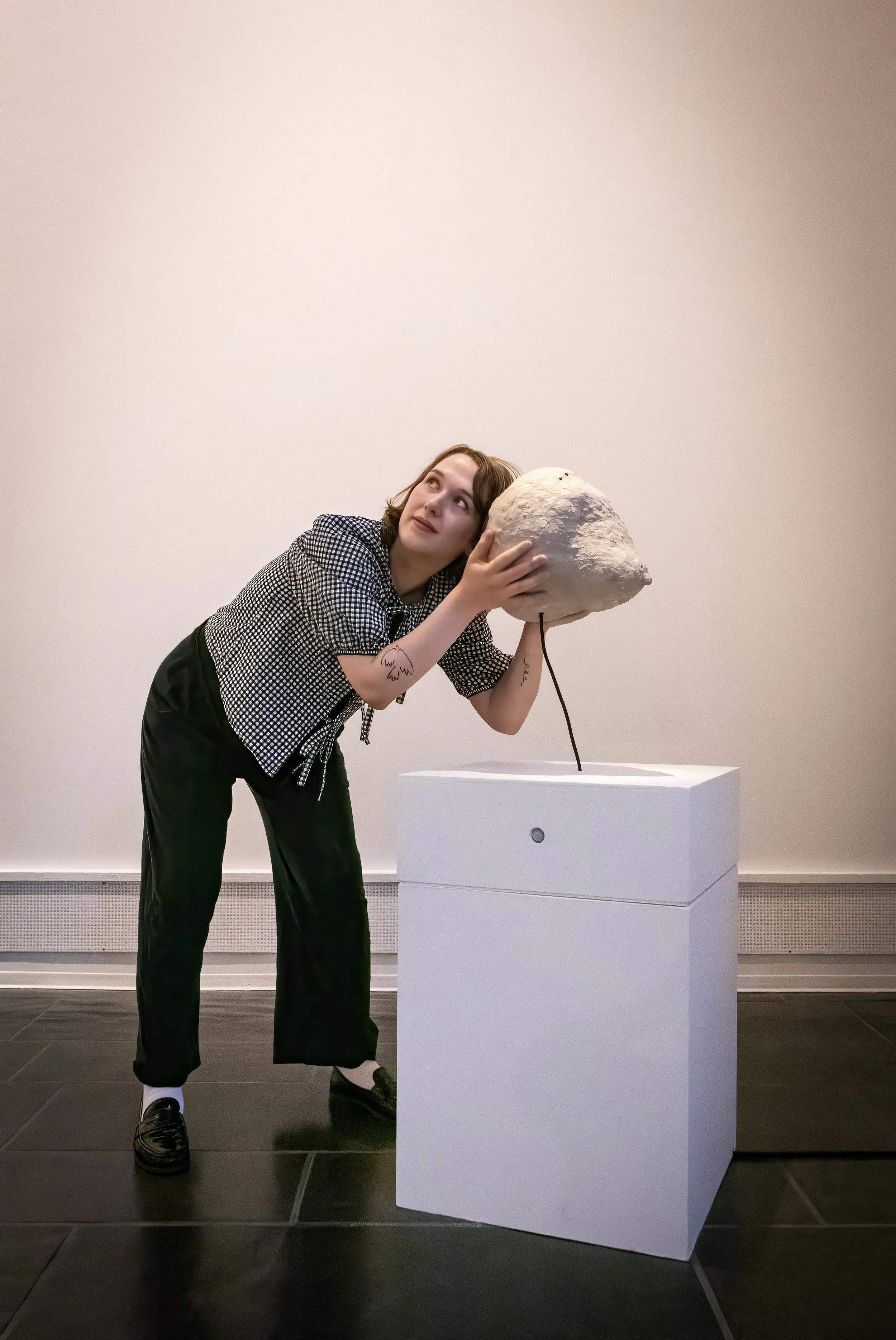

Bringing one of the 13 prefabricated units on site for assembly

Prefabricating the structure

We wanted to approach the making of our new micro-office as a full-scale architecture project and develop further our expertise in prefabrication and self-build techniques.The structure of the building is composed of 13 timber panels that were prefabricated in our workshop situated 50 meters (and 3 door frames! ) away, before being transported and assembled on the site,

One of the prefabrication manuals: we created one for each timber panel

Each panel was designed so that its size and weight would allow two people (Tom and me) to carry it on site safely. To simplify this, we created a small plugin for SketchUp to automatically check this as we modelled the structural panels, as well as to create detailed material lists and clear fabrication manuals for each module.

Assembling the construction

Once fabricated, each module was connected on site to the existing foundations of the former garden shed and to its neighbouring panels. It was then insulated with natural sheep's wool insulation, which was a real treat to install. The whole assembly was finally wrapped in wood-fibre boards for weather-tightness, extra insulation and breathability.

Section through the breathing wall construction

The interior climate is then simply regulated by natural ventilation (adjustable with vents in the door and skylight) and the heating provided by the waste heat produced by our computers. The whole wall construction is vapour-open, complementing the natural ventilation to maintain a healthy and comfortable environment inside.

Corner detail of the cladding, showing the interlocked broom heads

The broom cladding

The outside of the enclosure was finally clad with a total of 546 wooden broom heads, with natural coco-fibre bristles, screwed to battens wrapping around the breathing walls.

The selection of broom heads as a cladding material has been the result of a careful search for a material that would fulfil all our needs: a natural material with an interesting texture, readily available and affordable, friendly to the touch, yet resistant to break-ins by concealing any opening into the building.

Broom heads actually proved a rather economical cladding materials, as well as creating beautiful shades of browns and greys that evolve with the seasons and ambient humidity, reminiscent of some traditional thatching techniques.

Imagine, design, build and own...

Designing and crafting our micro-office Mission Control has been a long story: we started toying with the idea almost ten years ago! And it has sometimes been a frustrating one, especially when trying to fit this project between our other "more urgent" projects.

But, in the end, this has been an immensely satisfying project and something we are very proud of — having converted our initial idea into an actual architectural space that we love and truly feel our own, every bit of it designed and crafted with our own hands. A project that embodies many of our ethical values and architectural sensibilities at 2hD Architecture Workshop.